Applications and industries

Increased efficiency, downsizing and precision for various components with small bores are a must today and can only be achieved through highly specialized, state-of-the-art machining technologies. Microcut has the corresponding know-how and the necessary production facilities and machining processes.

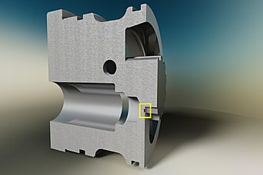

Automotive

Fuel and diesel injection systems (injector components)

Hydraulic control valves

Medical and analytics

Stents, capillaries

Ceramic components

Dental turbines

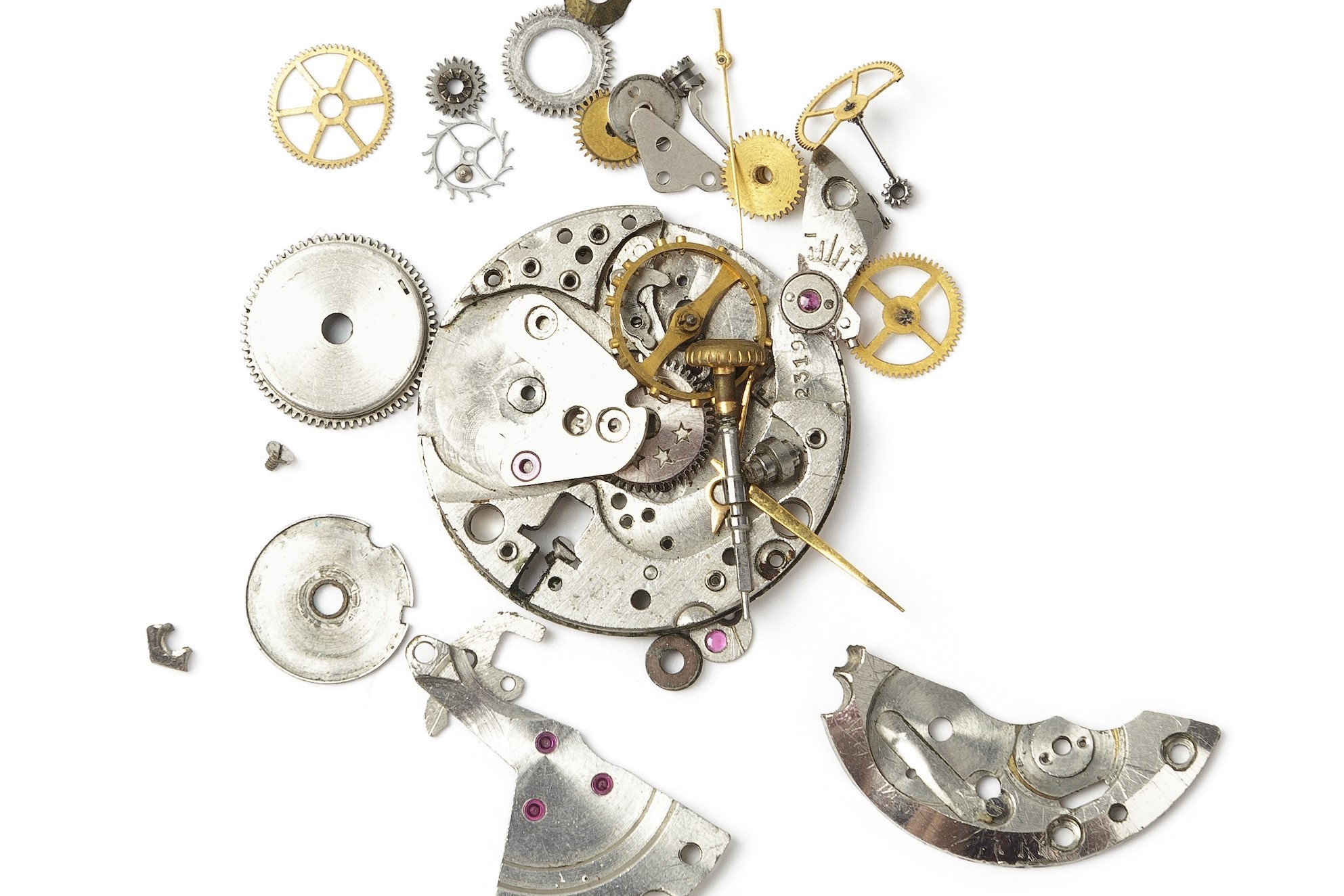

Watches

Gears

Bridges

Punching, pressing tool and injection mould construction

Punch bores

Ejector pin bores

Valve gate nozzles

Hot runner nozzles

Scribing tools for hardened glasses

Glass cutting wheels

Complete solution for fiber optics

Ferrules production

Aerospace industry

Regulating and control components

Hydraulic components