Services for small bores

Microcut: Process development, sample parts, contract manufacturing and service from one source

We have different types of machines and the complete development expertise in house. We are therefore highly flexible and able to execute services for small bores like process development and supply sample parts in a short time.

Microcut contract honing: Tailored to your series size

Here you will find the ideal solution for your application

We offer contract processing with our technology for customers who, for example

Microcut contract honing: The advantages

Microcut contract honing: Honing of hot runner nozzles

We are specially equipped for the finishing of nozzles and bushings in injection molds and hot runner systems.

Read the article “Präzision im Heisskanal“

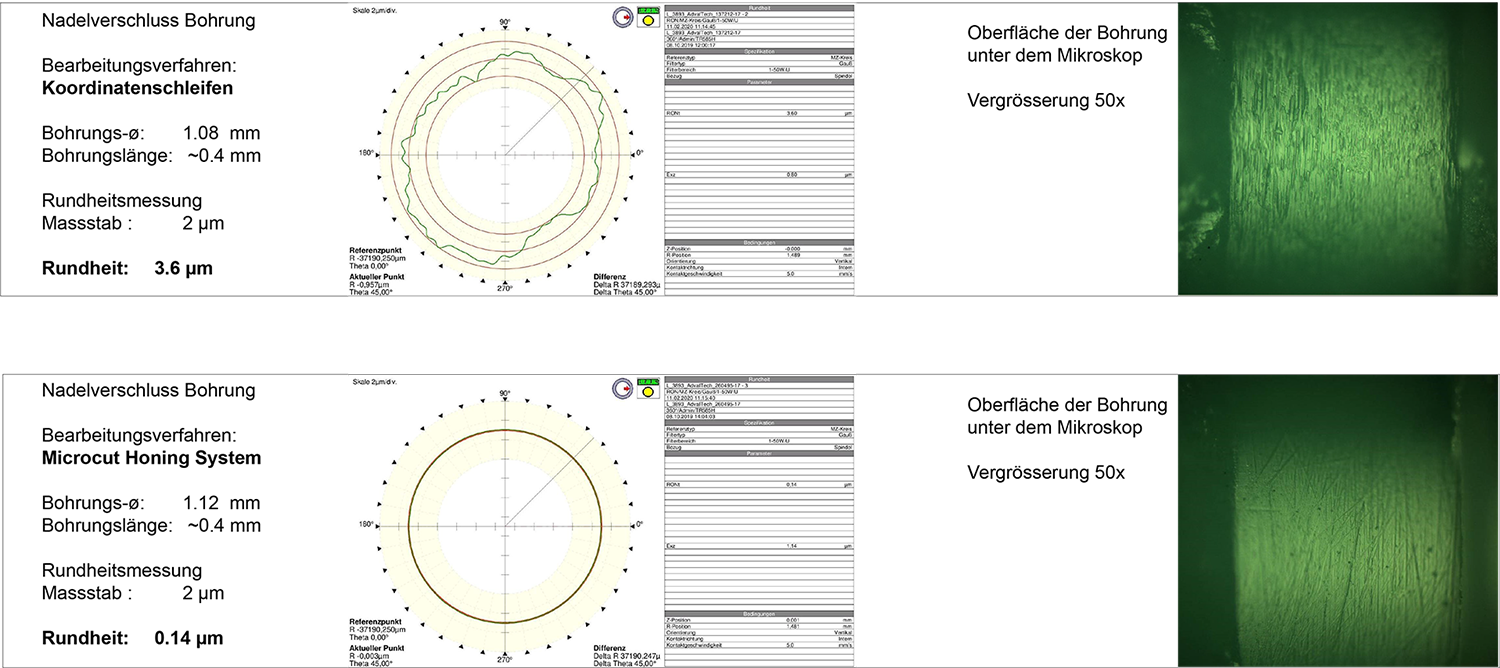

Above: Standard process at the customer’s site: Jig grinding

Below: Machining with Microcut Honing System