Microcut Honing System: Highest precision, easy to control

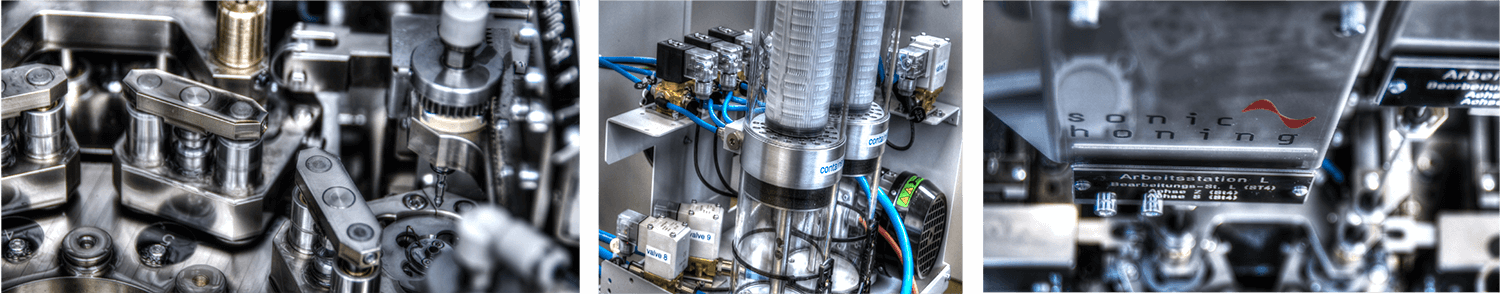

The Microcut Honing System developed specifically for smaller bores guarantees shape accuracy, surface quality and dimensional accuracy at the highest level even in series production.

Our technology has fundamental technical and economic advantages over established processes such as internal cylindrical grinding and long-stroke honing.

Especially for bores smaller than Ø 2 mm, where conventional processes such as honing and internal cylindrical grinding reach their limits due to the system, our process delivers previously unattained results.

With our unique innovative machining tools and the intelligent, force-sensitive control of the machining process, we offer an easily controllable and robust process with minimum dispersion.

The actual machining is carried out with tools coated with diamond or CBN grit (undefined cutting edge).

Our system is suitable for through holes.

sonic-honing technology: Highest precision AND productivity

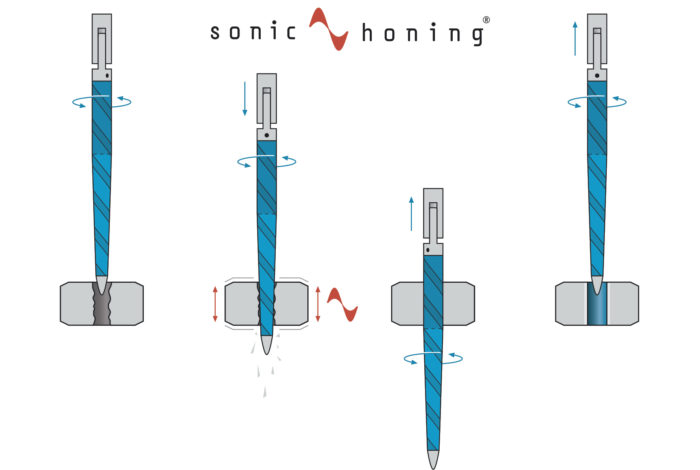

The sonic-honing technology is based on the Microcut Honing System and is suitable for specific applications.

We combine the adaptive feed control* of the tool with a fast stroke of the workpiece in the sound range. This enables us to achieve a massive reduction in cycle time, a longer tool life and finer surfaces with the same grain size.

*Adaptive feed control: The feed of the tool is controlled depending on the torque applied.

The control and evaluation of the process is managed by a highly sensitive force control and can, for example, detect and trigger the following

Workpiece clamping technology: A key factor

For difficult, e.g. thin-walled and small components, workpiece clamping technology is an essential success factor for achieving high form quality and automation. Microcut can offer various corresponding systems.

MICROCUT FACTS

FAST STROKE FREQUENCY

FAST STROKE AMPLITUDE

TOOL RPM

TOOL LENGTH (coated)

Microcut Honing System: The most important advantages

Advantages

Form:

Highest precision and process capability in terms of shape such as roundness, parallelism, straightness and cylindricity, even with interrupted bores or workpieces with cross bores.

Diameter:

Surface:

Very good and reproducible surfaces in the bore

Process control:

Why

Advantages

Very short processing times

Why

Advantages

Robust process even with bore diameters of less than 1 mm

Why

Advantages

Minimal system complexity

Why

Advantages

Various scalable automation options and easy integration with external automation solutions

Why

Advantages

Low space requirement:

Highest production capacity in the smallest space

Low energy consumption:

Why

Microcut Honing System: Achievable values

| Criterion | Achievable values with the Microcut Honing System |

| Diameter range | from 0.015 mm loose grit | from 0.25 mm — 8 mm bonded grit |

| Diameter tolerance | +/- 0.5 µm |

| Bore length to bore diameter | approx. 0.5 to 200 x D |

| Roundness | < 0.2 µm |

| Cylindricity | < 0.4 µm |

| Parallelism | < 0.4 µm |

| Surface quality | Rz < 1 µm with bonded grit |

| Cycle time | Depending on material, stock removal, bore length etc., typically from 10s |

| Parts Geometries | Rotationally and non-rotationally symmetrical |

| Materials | PCD, sapphire, ceramics, tungsten carbide, steel hard / soft, powder metallurgical steel, various metal alloys… |