Watch the video of our latest machine generation UniBore 900 – YouTube

Microcut is the reference address for high-precision finishing of small bores with honing machines.

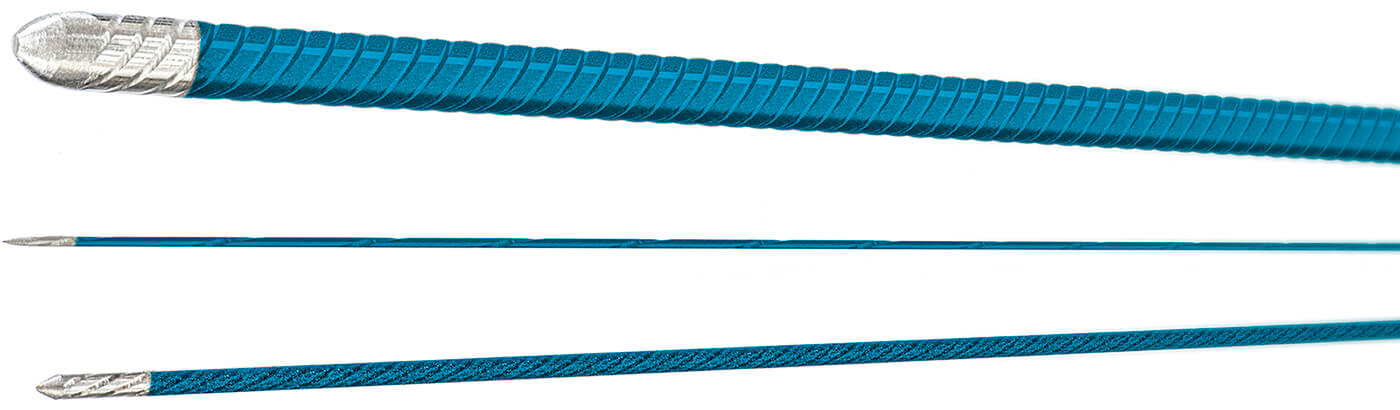

With passion we develop machines and tools for the efficient finishing of small bores with highest quality requirements for the diameter range from 0.015 mm - 8 mm. As a service we offer Microcut contract honing.

The Microcut Honing System for small bores is an easily controllable and robust process and guarantees minimum dispersion of shape accuracy, surface quality and dimensional accuracy. The Microcut Honing System, developed specifically for small bores, has outstanding technical and economic advantages over established processes such as internal cylindrical grinding and conventional honing. In 2019 we proudly presented the sonic-honing technology, which combines highest precision AND productivity. With this development stage, the cutting performance could be increased by factor 4, the surface roughness improved and the tool life extended.

With the Honing Module MH©cut we bring our 4.0 technology directly onto a machine tool, such as a hard turning lathe, thus enabling complete finishing in one clamping. In the course of the general miniaturization of components, the Microcut Honing System offers solutions for small bores, where established methods reach their limits due to their principles.

An ever-increasing demand for quality, with high cost pressure, can additionally favour a process change to the Microcut Honing System. Low tool costs per bore as well as low space and energy requirements of the systems underline the sustainable customer benefit of our technology. The process is suitable for small quantities, e.g. in tool and mould making, but also for large series in the automotive industry. Our machines are modular and scalable.

Due to the easily reproducible, exceptionally good shape accuracy, the demand for Microcut machines for larger diameters is also increasing. The advantages are particularly evident in interrupted main bores with releases and cross bores, such as in hydraulic control components.

MICROCUT FACTS

TOLERANCES

DIAMETER

MACHINES

PRECISION (DISPERSION)