Microcut machines: Exactly according to your needs

The machine is typically configured to customer requirements according to the following criteria:

Checklist for Microcut Honing System

With this checklist we can assist you to find the best solution for you. We will contact you shortly.

Microcut machines: Modular and scalable

The machines are modular and scalable in terms of bore diameter and series size.

The number of spindles depends on the series size, the stock removal or the diameter range.

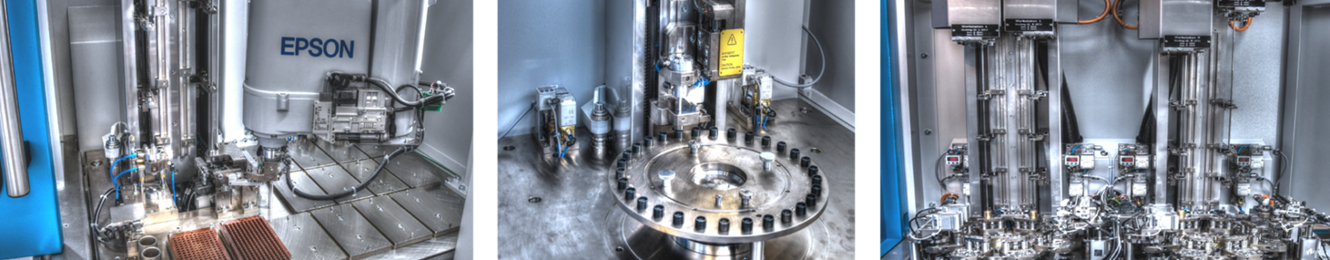

Microcut machines: Automation included

The machines are designed for automation from the ground up and integrate scalable part handling directly in the machine.

Besides manual loading, the following automation options are common:

Microcut machines: A selection

Below you can find brochures for selected machines. Typically, the machines are configured individually according to customer applications.

UniBore

UB831-M

Precision honing machine with one honing spindle and highest flexibility regarding part variety for manual loading

Machine for the machining of holes with diameter:

0.25 – 8 mm

UniBore

UB834-S-2C

Honing machine with sonic-honing technology for highest productivity

Machine with up to 4 honing spindles and 2 round plates for fully automatic loading of holes with diameter:

0.25 – 8 mm

UniBore

900

Honing machine with sonic-honing technology for highest precision, productivity and autonomy with integrated automation solution

Machine for bores with diameter:

0.25 – 8 mm

MicroTube

1700

The solution for the internal machining of Nitinol tubes

Machine for honing Nitinol tubes with inner diameters from 0.8 mm to 8 mm, lengths up to 1700 mm and wall thickness from 0.1 mm to 0.3 mm

MicroBore

125

Over 120 times in daily series operation

Machine for machining the smallest bores of

diameter: 0.060 – 0.150 mm

For technical information please contact us.

MicroBore

20/50

For the smallest bores

Machine for machining the smallest bores of

diameter: 0.015 – 0.060 mm

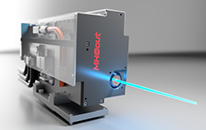

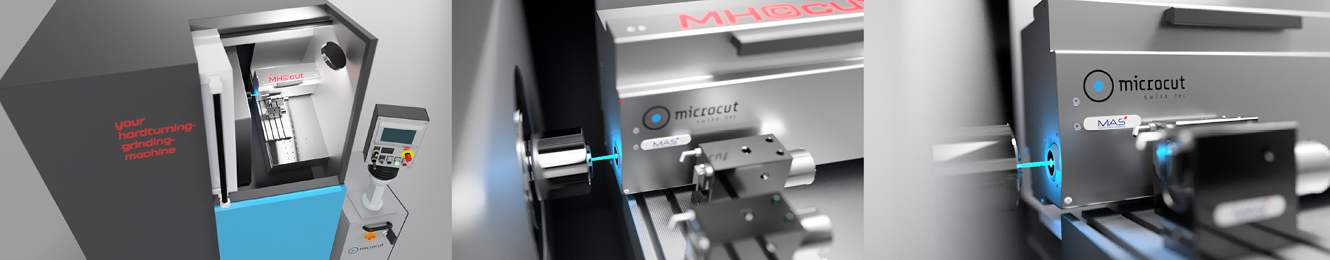

Microcut honing module: Combined processing

With the Honing Module MH©cut we bring our 4.0 technology directly onto a machine tool, such as a hard turning lathe, thus enabling complete finishing in one clamping.

Honmodul MH-Cut©

Produce cylindricity and roundness µm-accurate in series for bores of

diameter 1 – 4 mm